Wideopen Interview

January 18, 2016

Wideopen is one of the UK's best independent Mountain Bike websites, run by a small group of mates and dedicated contributors. They wanted to interview me to find out a bit more about Airdrop Bikes...

Who is Ed Brazier?

A 35 year old, slightly introverted ex-designer who loves riding bikes and making things.

How did Airdrop come about?

I was never comfortable with the idea of working for someone else; it felt a bit like cheating. I needed to know if I could live by my own wits and not rely on other people to make things happen. I used to get frustrated when the business I worked for went in a direction I didn’t agree with, and I was powerless to affect change. There was really only one way to solve that.

I had this idea of what sort of place I wanted to work. A small group of people: like minded, talented, good friends. All working on something we really believed in, something worth doing well. Not just about money, or profit, or winning; something with a bit of substance and integrity. Importance would be placed on quality of life, good service, making cool stuff and inspiring other people. And of course, bikes. There had to be bikes.

Maybe that was a bit naïve, and although I worked at some cool places, it was never like that. So I reasoned if I wanted it to be that way, I’d have to make it happen myself. I knew it was a big task and I needed both skills and experience, so I did my job, learned as much as possible and every month I set a bit of cash aside towards the goal. After 12 years I was in a place where I felt maybe I could just about do it, so I jumped.

What's your background in cycling?

I’m not from the industry, or at least I don’t see myself that way. I definitely feel like an outsider.

I grew up in a rural village, surrounded by fields and a decent set of hills outside the back door. To us, bikes were the best way to get around on our adventures. I had three brothers and a bunch of mates living nearby, so we rode all the time. I guess I grew up as an outdoors kind of kid. When my brothers went to Uni they got into climbing and mountain biking, so naturally I wanted to follow them. It was the early ‘90s and I was still only 12 or 13, but I saved up and bought a second-hand ’92 Orange Clockwork out of the local newspaper. That first proper bike enabled me to go to the Lakes with them and it was properly old-school: tape some pipe lagging to the top-tube, shoulder your bike and carry it up Helvellyn. Eat your sandwich on the top then carry your bike most of the way back down again. Actually I’m not sure why I enjoyed it so much!

I used to get MBUK every month but the thing that really interested me was the bikes, the materials, the technology. I’ve always been into making things so I was attracted to the bikes and kit as much as the riding. I could never afford any of the anodized drillium bike-bling, but I knew all about it.

So I went off to Uni and came out of it looking for a job. I applied for two: one in a bike shop and another in an outdoor shop. I got the outdoor shop job so that set the direction for the next few years. Climbing took precedence over riding, although riding never went away completely. I was in Sheffield after all. Eventually climbing waned for me but riding has always been there.

A couple of years ago I spent some time riding out in Finale Ligure, and it was a real eye opener. I went out there on my 125mm trail bike with (what is now) dated geometry and components designed primarily to be light. The riding was amazing and the bike just about coped, but by the end of that trip it was obvious that this was the kind of riding I wanted more of, and a different breed of bike was required. I can’t wait to get back out there with an Edit.

Just how 'hand-made' are your frames?

We’re not talking full bespoke, one-at-a-time here. I have huge respect for traditional frame-builders, but that way isn’t right for Airdrop. The frames are made in batches in a small factory, where very little of the process is automated. The tubes are cut and mitred with manually operated machines, the jigs set up by hand and the frames welded by hand. These guys have 20, 25 years experience doing this and they’re extremely good at it. There are CNC components of course, but even those are produced one at a time on a small machine. So I’m not saying they’re artisan-made, but neither is it full-on mass production. It feels just right.

When you place an order, your frameset, bundle or bike is assembled and checked by hand here, so there’s a human involved at every step in the process. There’s this perception that online-only businesses are somehow robotic and impersonal, but I’m saying it doesn’t have to be that way. You may buy the bike on the web but there are real people behind it.

How did you choose the factories you work with?

Finding the right suppliers was one of the hardest parts to get right. When I started out I didn’t have any connections or contacts at all, so it was a standing start. But that’s part of what attracted me to the whole challenge; it was a really tough nut to crack but I wanted to see if I could do it. There was a lot of cold-calling, and the hardest part was getting anyone to take me seriously: some guy you’ve never heard of, with no brand, no reputation and no money. He says he’s setting up a company... Time waster. And I didn’t even know how this stuff is normally done, so it was a steep learning curve.

There was a fair bit of rejection, but a few factories opened up a bit and were prepared to talk. I shortlisted three factories and while I was developing the early designs for the bike, I was working with them to understand what was possible. My first choice looked great; it was a big-name factory, making some of the best bikes out there, and we went as far as a prototype. But after a few months they pulled the plug on me and never gave a reason. That was a heavy hit at the time, but I’m glad it happened, because I learned a lot from the experience. It’s what made me go for a smaller, more personal factory, who would see the project as being more important to them. They turned out to be super-positive, receptive to everything I wanted to do and it was like a light-bulb going on. The first factory had been rubbish. These guys were great.

Why small batches?

The obvious reason is finance. Airdrop is properly independent, there’s no distributor in the background, no retailer or private equity investor. There’s just me and my savings. So one of the limitations was always how much cash I have to put into production. Most factories have a minimum order quantity per batch and per size, so that set the framework.

There are some real practical benefits too, so I embraced this limitation as a positive. Firstly it enables Airdrop to stay away from model-years. If I want to make an improvement, I can do it on the next production run. I can do different colours or a limited edition. It means we’re agile. I won’t have a glut of stock at the end of a season and I’m not committed if something changes. Why are so many big brands still selling short, steep bikes? Because they ordered 100,000 of them two years ago. It also means I’ll be able to try stuff out and have a bit of fun with projects, be creative and see what happens.

How many people make up Airdrop and what do they do?

Right now it’s just me. Airdrop is a one-man-brand. I actually wanted it to be this way, to start from nothing and build from there. And in a way I wanted it to be a test, I wanted it to be hard. The whole idea seemed ridiculously difficult, but not impossible, and that’s the challenge that I was looking for.

I’ve got good experience from previous jobs so there are things that I’m comfortable with, but there has been a huge amount of learning. I was always told “you can do anything if you set your mind to it” and although it may sound crass, I actually believe that. But I’m also pragmatic and this is a serious business, so if I need specific help, I‘ll go out and find someone who really knows what they’re doing. For example I’ve got a top design engineer who advises on suspension kinematics and engineering, just to make sure I’ve got everything locked down.

What did you have to sacrifice to get to this stage?

Nothing important. A few years back I’d have given a different answer. I was a head of department at a big company, I had a great team working for me, a good salary, blah blah blah. I’d worked bloody hard to get there. Eventually I realised that all of it was meaningless because I had a rubbish quality of life. That really came into focus when my daughter was born; I was leaving early in the morning, coming home late, knackered and stressed. I was missing out on the best bits just to make some other guy rich.

I packed in the day job and all the stuff that goes with it. Money, status, routine, security. I put my entire life savings into Airdrop, but I’ve never been happier than I am now. I get to walk my daughter to nursery every morning, then spend all day working hard on something I really believe in. If I want to go for a ride, I can just go. Sometimes I even have to go for a ride, because it’s my job.

The only thing that I found hard was selling my camera gear. I was seriously into wildlife photography, and spent years scraping to build up a good system of bodies and glass. I finally managed to get one particular lens which I’d been dreaming of for years. When I decided to go for Airdrop I knew I needed the money and I couldn’t afford the distraction. So I sold it all - including the dream lens - which I never got to use. It was hard but ultimately, it’s just stuff. Nothing important.

Did you have day jobs that you had to give up?

Yes, I had what looked from the outside like a great job, but I don’t see it as something I gave up. I was ready to stop doing that and although it was a big decision, it was definitely the right thing to do.

Are you working alongside to make ends meet?

For the first month I rode my bike every day. It was summer and I’d been working for 12 years without more than a two week holiday. I was burned out and I needed to reset. But I had a family to support, a mortgage to pay and a business to build so I set up as a freelance designer. It kept my eye in, kept the wolf from the door and made me some new contacts which has been helpful. Eventually Airdrop became more demanding, and I knew that I had to commit fully to it. I didn’t want to fall into the trap of Airdrop becoming a hobby, so I finished up my projects and went into Airdrop full-time; I think I needed that level of commitment to really make it happen. I’ve always thought if a thing’s worth doing, it’s worth doing well, so Airdrop had to have my full attention. I can’t hide that it’s been difficult financially, but I’ve got it in perspective, and if Airdrop is a success, I’ll know I’ve earned it.

How make or break is the company for you?

I’m fully invested in Airdrop. I’ve put in my entire life savings, 18 months of my life and I’ve told the whole world this is what I’m going to do. I don’t want to fail.

You worked 12 years as a designer, what sort of design work did you do and how did it help with Airdrop?

Over the years I’ve been a web designer, a graphic designer and a design manager, so there are a bunch of specific skills that speak directly to what I’m doing with Airdrop now. I’ve built websites, worked in e-commerce, retail, marketing and I’ve developed a bunch of action-sports brands, and all that experience has helped. But I think those specific things are less important than the core designer skills. Knowing how Creative Suite works or being able to write HTML doesn’t make you a designer; those are just the tools you use. Being a designer means you can identify a problem, really interrogate and understand it, then work through a process to develop a solution. Very few people can start with nothing and come up with something, much less something meaningful. That’s a skill you can apply to any problem and it’s that approach that has seen me through all the challenges that Airdrop has thrown at me.

I also formed my own view on how business should and should not be done. There were many things I didn’t agree with, thought were cynical or too hard-headed. It helped me build that vision of what sort of business I want Airdrop to be.

How did you learn what you needed to know to get your own company off the ground and the bikes in hand?

I’ve always been interested in bikes, the way they’re made and how they work, so I came to it with a good background knowledge of the technology. But I also really like to learn new things, so I immersed myself in current thinking on bicycle geometry, handling and suspension kinematics. I analysed every significant bike on the market, how they had been reviewed and received, and rode as many as I could get my hands on. I sought out other people’s opinions and listened as much as possible. It was important to really question the received wisdom though, to not just take what you read at face-value. Eventually you get enough knowledge to start trusting your own judgement.

On the business side, I’ve worked at a couple of really fast-moving companies, where it was possible to learn about building a business if you really wanted to. I was lucky; the people I worked for gave me chances and were generous with their knowledge. And of course the big reason I wanted to do this in the first place was so I could be making the decisions.

The nuts & bolts of actually setting up a business were a mystery to me so I had to learn a thing or two there. There’s a lot of talk about government supporting new businesses but that’s all it is: talk. They don’t half make it difficult for you. I think it’s like a test – only the ones who really want to get up and running will get through all that red tape.

There’s no substitute for getting stuck in, and there was a lot of trial & error. But you just have to keep going, whatever obstacle there is: keep going and you get there in the end. Have I made mistakes? Undoubtedly. I spent a whole month scraping mould off the walls of the workshop, only to decide to board over it. But you’ve got to earn your turns. I’d say that determination is more important than any specific skill when doing something like this.

How many prototypes did you have before getting to the production Edit?

The bike that we have now is more or less the third generation Edit. The rear triangle is the fourth physical version. There was always a limitation on how many samples we could do – it’s incredibly expensive – so there must have been hundreds of iterations of the design over the last 18 months. The key has always been to work hard, be smart and make every penny go as far as possible.

I suspect that big brands with big budgets would do more, but of course you have to charge your customers for that. And I’ve got to say there are some brands that do a lot less, that’s for sure. Ultimately I only went into production when I felt that the Edit was ready to go.

Beyond the development of prototypes, what form did your testing take?

Riding riding riding. I tried to get as many people as possible riding the bikes, from different backgrounds and skill levels, on different kinds of trail. Friends, family, total strangers, industry people. I tested different shocks, different tunes, different build kits. I did cheeky blind tests where I didn’t tell people what the size or geometry was, because they tend to interpret the numbers then tell you what they think they mean. I did back-to back tests on the same sections of trail up and down, over and over again.

Bike testing is an extremely challenging thing; a moving bike on rough terrain with a dynamic rider has so many variables it’s almost infinite. You can only be scientific with it up to a point. Don’t believe anyone who tells you they’ve got something totally optimised. Isn’t that the best bit though? Bikes just keep getting better and better, there’s no limit.

My goal was to produce a bike that’s fun to ride and that’s not something you can put a measure on, but you can tell when someone’s enjoying a ride and when they’re not.

The other side of testing is to ensure that the frames are compliant with the relevant regs, strong enough, stiff enough, have enough clearances and so on. They’re EN tested in the far east but they’re also going to Bureau Veritas in the UK for a belt & braces approach.

Where next for Airdrop? How do you plan to go about getting extra helpers etc. etc.?

There is another bike in the pipeline, which I’ve been developing for a while. I’m not saying what it is right now, but it’s going to be rad.

It’s hard to say what the next few months have in store, because I really don’t know how many people are going to buy into the Edit. It could be a real slow burner, or it could go nuts. There’s only so much I can do myself, and part of the big idea is to get that group of people together, so I’m definitely looking to bring other people in. That’s something I’m really stoked on, to get people into a place where they can really contribute and make a difference.

Whatever happens, I’ll be enjoying it. I ‘m going to try to get out on my own bike as much as I can, and make some great content to share. There are plans afoot for a video, there’s talk of an epic trip, and Finale is always calling…

Anybody to thank at this point in the Airdrop journey? Long suffering spouses/parents/friends?

I’ve got to thank my wife Muniza first and foremost. I hope she hasn’t suffered that much! She’s been incredibly supportive and never questioned whether or not I could do this. My family and friends who’ve put up with the endless bike talk, absences from important social occasions and general obsessiveness. Lasty I’d like to thank the suppliers who didn’t hang up on me, who were willing to take a chance and give me their support.

Interview conducted by Pete Scullion on behalf of Wideopen, December 2015. You can see the original feature on the Wideopen Website.

Ed Brazier

Ed is the owner of Airdrop Bikes. A former web and graphic designer, he sacked off his job one day and decided to start up a bike brand.

1 Response

Leave a comment

Comments will be approved before showing up.

Also in Airdrop Bikes Blog

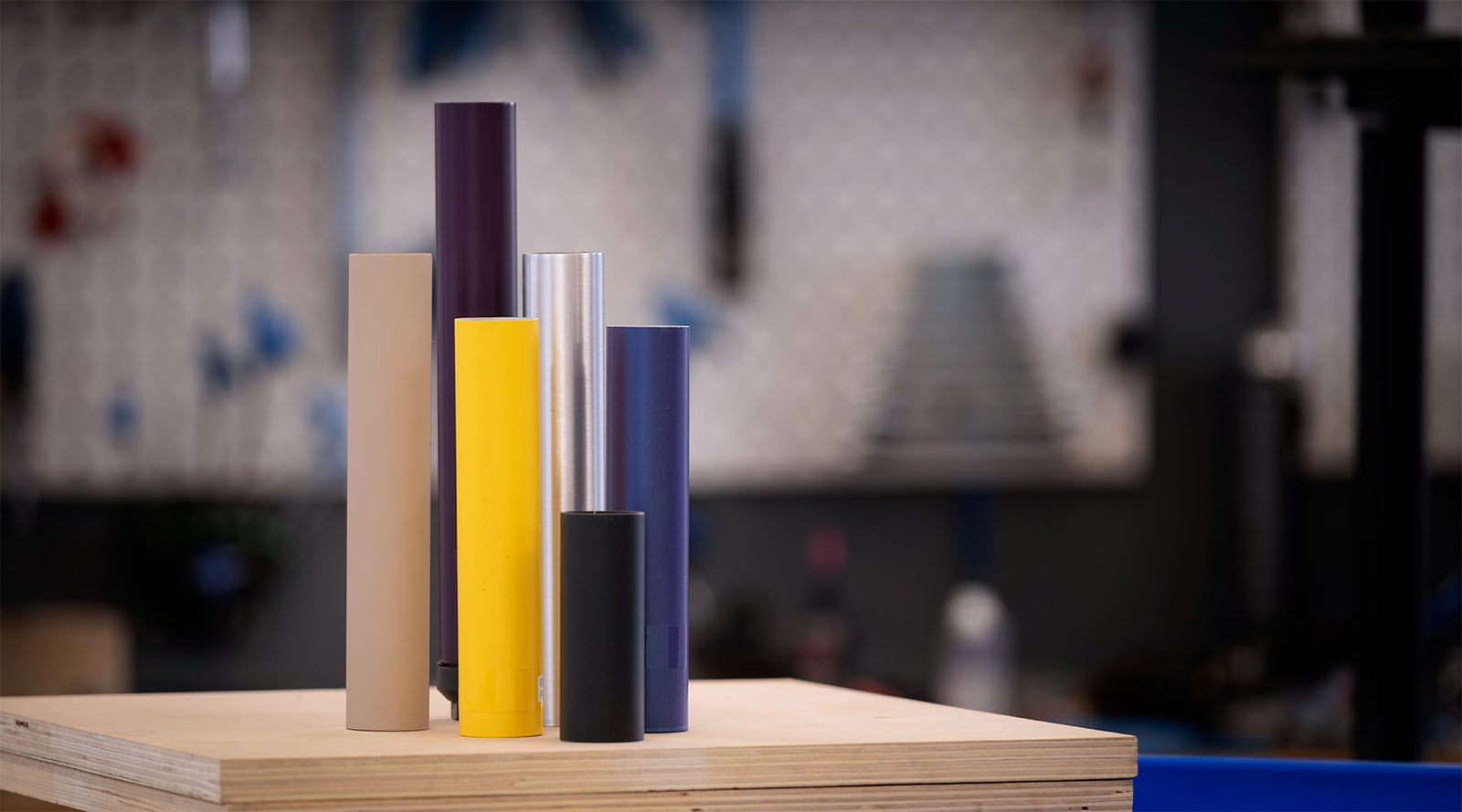

New Frame Colours

February 18, 2025

With new batches of Edits and Slackers coming in (Fades just arrived), we've taken the opportunity to freshen things up with new colours.

Read More

Introducing Alf Raynor

February 12, 2025

We're stoked to announce that Alf Raynor is riding for Airdrop Bikes. Alf is likely the hardest man in MTB, he loves the Graft and goes hard on the build. His Raw style on the bike and commitment is something that has to be seen to believed; it's wild.

New Batch of Edits Incoming

February 07, 2025

The new batch of Edit frames is complete and is on it's way to Sheffield. We've taken the opportunity to freshen things up with all-new build options and colours, and preorders are now open.

Email Newsletter

Our monthly email newsletter gets you access to all the good stuff before everyone else.

Get The Inside Line

We're always working on stuff behind the scenes and we'd like to share those stories with you. One email a month, and we make it worth a read.

Sign up to get the inside line.

Jon Walker

January 21, 2016

Sounds awesome Ed – the Edit, your story, the philosophy and direction of Airdrop!! I’m buying one of your bikes as soon as I can (bear with me, I’m setting something up like you, but replace bikes with wood). Catch you soon, Jon